Home / Managing Production

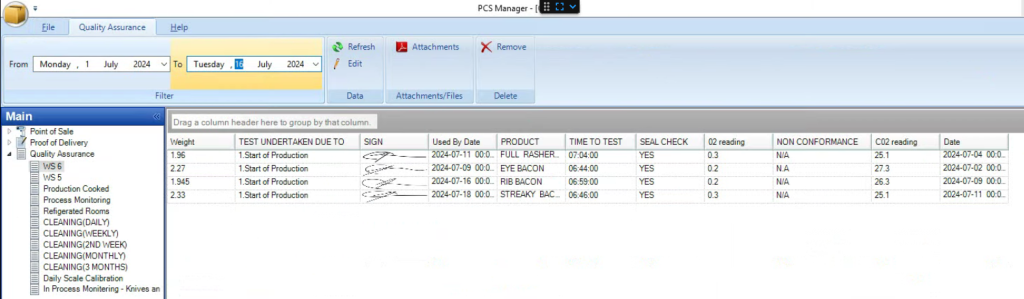

ExPCS QA Module eliminates any manual paperwork, and forms that are currently used for HACCP, SQF or any other QA systems. We digitise all your paperwork and use mobile Tablets with live connectivity like Wi-Fi 4/5G Capabilities to send collect form data back to the system.

The QA auditor then can report on all data collected in the defined format required in the back office and make sure all data is collected effectively.

We have ability to schedule form collection email alerts and warn on missed data entry that was planned.

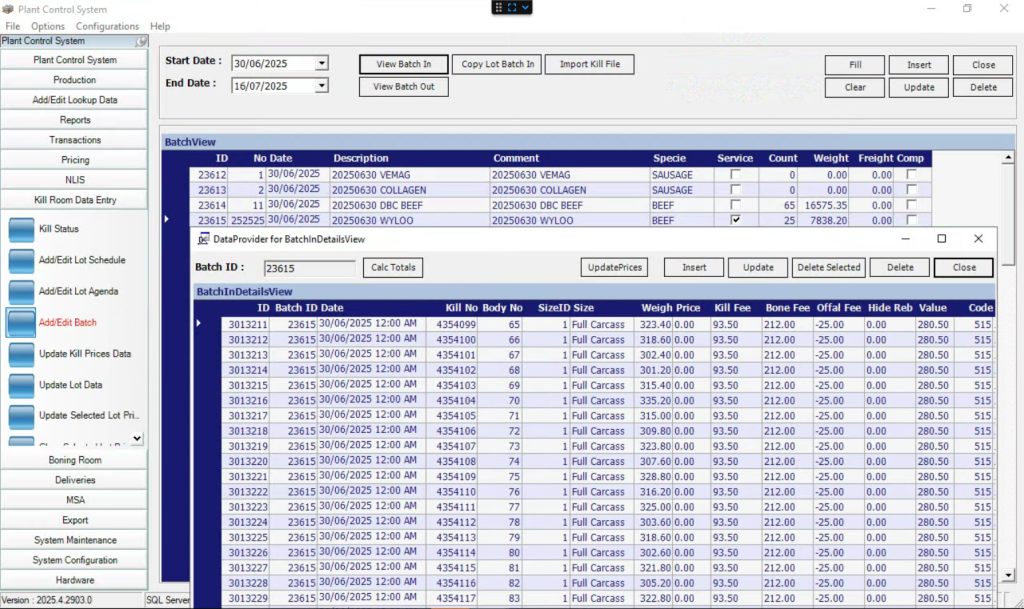

ExPCS Batching & Yielding Module is part of the Production feature set and allows any production process that has an input and an output to be properly quantified and assist making sure the process is profitable. Some of these processes could be Carcass Boning, Food Value Add Processes, such as Portioning, Crumbing, Corning, Marinating, Burger, Sausages Making, and many more.

The batching and yielding are live, with batching and yielding of Weight as well as Cost and profits. The process is streamlined, easy and fast to use by production staff on touch screen computers, tablets and mobile computers.

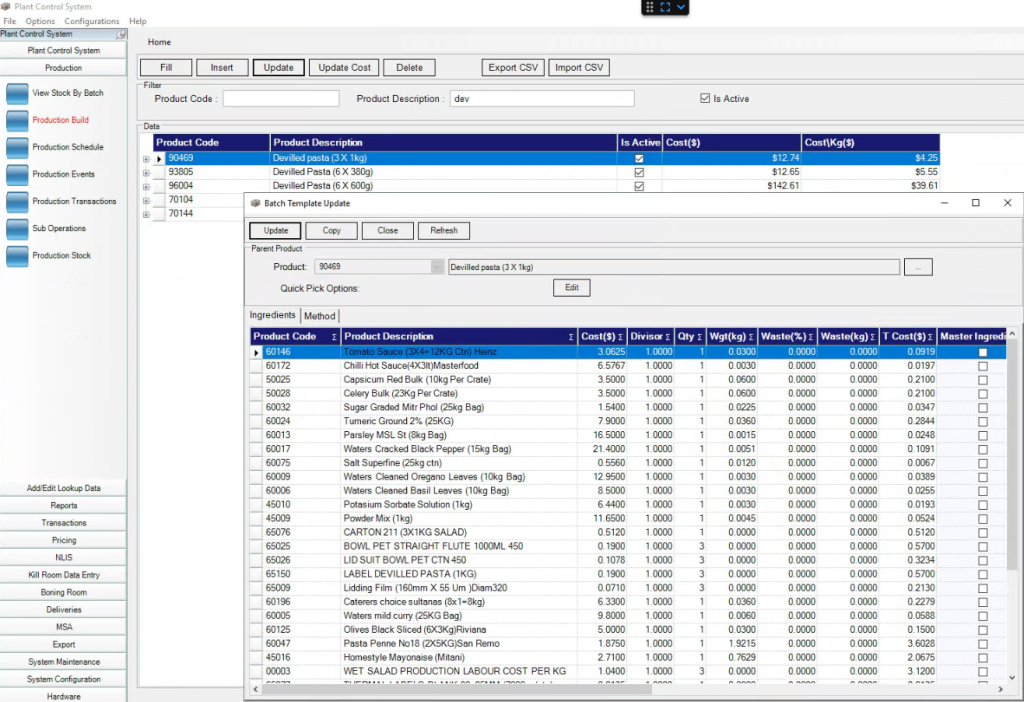

The ExPCS Recipe Management Module is feature rich and fit for purpose. It has ability to use ingredients, costing, Instruction linked to various process stages, Cater for Waste by weight or percentage, Record Ingredients batch numbers and Production dates are options, Master Recipe Ingredient, Barcode Scanning, Scales, Manual Entry, Printing of pick list, Recipe within a Recipe (Multi-layer recipes).

The ExPCS Recipe Management Module works on touch screen computers, tablets, and mobile computers, and provides mobility where needed and fixed mount capabilities where necessary.

The ExPCS Recipe Management Module is also linked to our Production Planning Module.

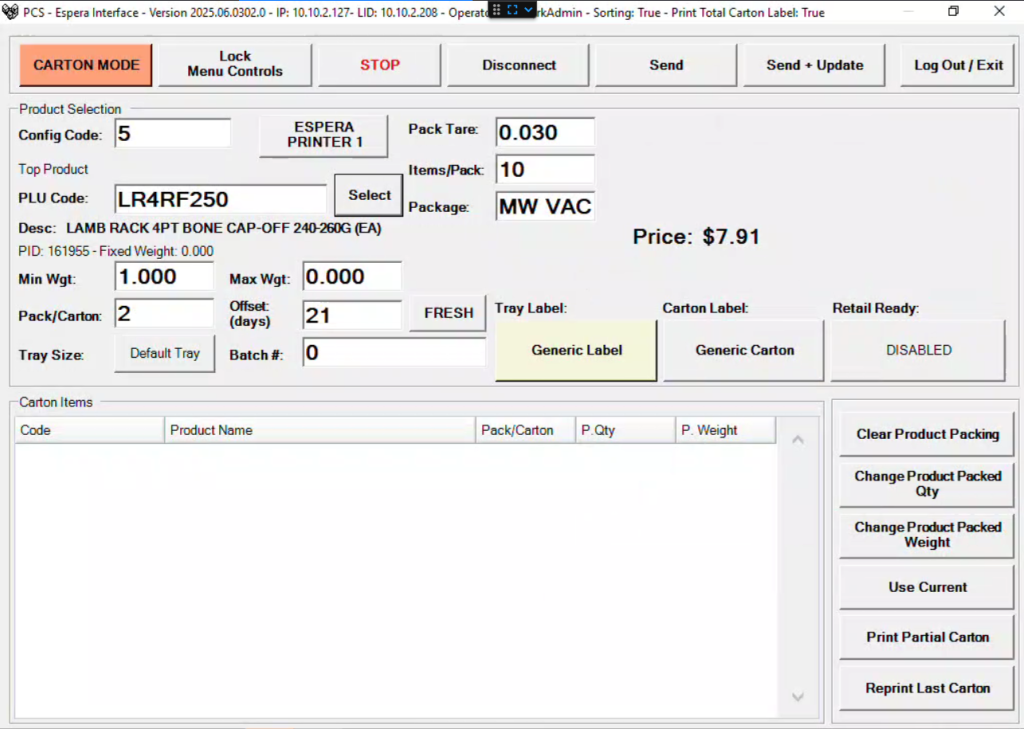

The ExPCS has tight integration with various production equipment, like: Platform Scale, Floor Scale, Rail Scales, Inline Weight Labeller, X-Ray Machines, Metal Detector, Print and apply Label applicators for Carton/Pallet automatic labelling, Barcode Scanners, Unattended Barcode Scanner over conveyor belts, Grading Equipment, Multi Weigh Header, any many more, this is a true agile system with limitless connectivity.

Some of the brands we work with are : Wedderburn, Digi, Espera, Bizerba, Dibal, Ishida, Toledo, Marel, AnD, and many more.

On premises server deployment that implements the standard features needed to run your inventory, manufacturing, shipping and receiving. Ideal for smaller single site companies that need to solve batching and inventory issues (inconsistency, poor quality, scrap or wasted products). Supports limited hardware.

On premises server deployment that implements the advanced features needed to run your inventory, manufacturing, shipping and receiving. Ideal for larger site (or multi-site) companies that need to solve batching and inventory issues (inconsistency, poor quality, scrap or wasted products) and advanced warehouse management. Supports unlimited hardware. Allow unlimited, real-time exchange data with ERP or Accounting software.

EXCELLENTTrustindex verifies that the original source of the review is Google. Great people, expertise, advice and support. Existco has to be number one on your list for supply chain optimisation software development.Posted onTrustindex verifies that the original source of the review is Google. Both Existco Platforms PCS and SMS, have been such an efficient addition to our business, simplifying and empowering our operators to produce efficiently created products and providing fantastic management and sale of these product, the whole Existco team are quick and easy to work with in correct and future proofing any issuesPosted onTrustindex verifies that the original source of the review is Google. ExPCS has transformed our business! As a meat wholesaler and boning room operator, efficiency and reliability are absolutely critical to our operations. Since partnering with EXPCS, we've seen a major improvement in how we manage our technical systems and workflows. Their team understood the unique challenges of our industry and delivered tailored solutions that streamlined our processes, reduced downtime, and improved overall productivity. From hardware setups to ongoing support, their service has been exceptional. Eli and the team have been responsive, knowledgeable, and genuinely invested in helping our business succeed. Thanks to ExPCS, we now have a more stable and scalable tech environment that supports our growth. Highly recommended for any business looking for reliable IT support with real industry understanding!Posted onTrustindex verifies that the original source of the review is Google. The team at Existco, especially Eli, are so great to work with for all of my problem solving, trouble shooting, and feature development needs. They really aim to understand how our company operates to be able to recommend the most efficient way to use the software. Feels like they're a part of our team even though they live several states away!Posted onTrustindex verifies that the original source of the review is Google. Powerful Platform for Wholesale Meat Processing Operations Existco ExPCS has transformed how we manage production, inventory, and sales in our boning room and wholesale meat carton business. The system offers full traceability, streamlined order fulfilment, and seamless QA/HACCP compliance. The advanced reporting and ordering portal give us real-time insights and make customer interactions effortless. Highly recommended for any meat processor looking to modernize and scale efficiently!Posted onTrustindex verifies that the original source of the review is Google. ⭐⭐⭐⭐⭐ Exceptional System for Abattoir & Boning Room Operations! Existco’s EXPCS platform has been a game-changer for our abattoir and boning room operations. The system handles service kill and service bone workflows with precision, giving us full traceability from livestock intake through to final product dispatch. It’s incredibly powerful for managing production data, ensuring compliance, and maintaining quality control across every stage. Sales and order fulfilment are now streamlined and fully integrated, allowing our team to manage customer orders, inventory, and dispatch with real-time accuracy. The traceability features are especially impressive—every cut, carcass, and carton is tracked, which has greatly improved our reporting and accountability. The support from the Existco team has been outstanding. They understand the unique needs of meat processing facilities and have delivered a solution that’s both robust and easy to use. Highly recommended for any abattoir or meat processor looking to modernize and gain full control over their operations!Posted onTrustindex verifies that the original source of the review is Google. Worked with Eli and his team as we are currently rolling out a new system. Eli and the team have been lovely to work along side of.Posted onTrustindex verifies that the original source of the review is Google. You have a beautiful system, Eli. I was told today by a customer we deliver old stock to him I told him we don't carry stock so it's not possible. So, I asked him to send me the photo of the meat he is talking about. I then went into the system and showed him that that meat was packed on Monday with the exact Time, date expiry date, weight and with the store name and forward it to him I while later he came back to me apologizing as his staff did not pack the meat out when they had to and this way I could proof to him that we pack fresh every day and how accurate we can trace one packed of meat just by having its photo of the product. For us this was a very good result because not only did it show us how good our traceability of any product at any time is, but it also gives us the confidence that we can demonstrate how sufficient our system is in backing us when the time comes to do so. Thank you so much to Eli and his dedicated team for making this possible. I would recommend this system to any meat processor out there. You cannot go wrong.

If you have any questions or queries. Feel free to email us via the contact form or call us on +61 8 9227 0088

08 9227 0088

sales@existco.com.au

10 Weir Road, Malaga, WA, 6090